Over 25 years of delivering superior strength & quality components using our unique capabilities and expertise in flow forming, metal spinning, rotary forging, and shear forming. Let us help solve your project challenge by customizing a solution for you.

Our Custom Forging & Forming Capabilities

Near Net Shapes

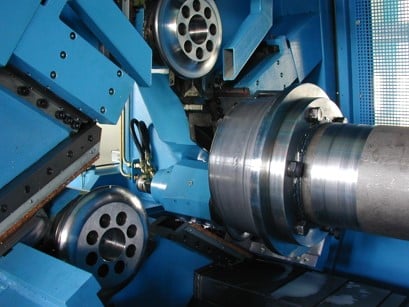

CNC rotary forging presses offer near net shape forgings up to 56” diameter.

Rotationally Symmetric Shapes

Spin/flow forming machines, creating a wide variety of rotationally symmetric shapes with a high degree of material efficiency up to 60” diameter and 130” length.

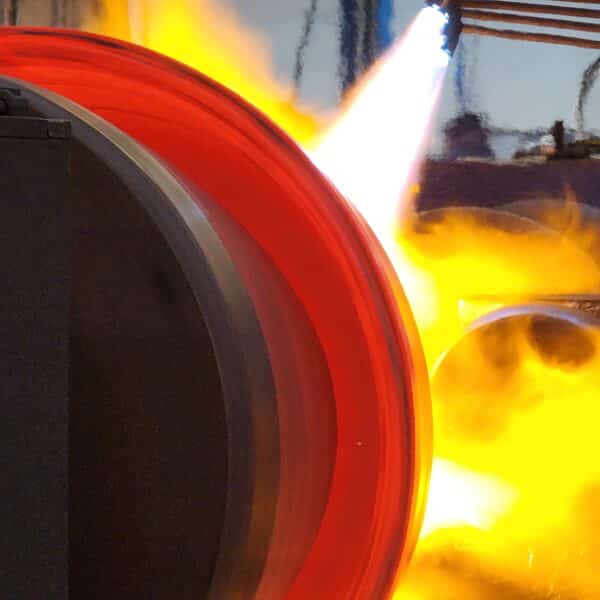

Large Diameter Tubes

Our machines can create large diameter tubes and nozzles for high profile space applications, oversized military wheels up to 35” in diameter, and forged wheels up to 34” in.

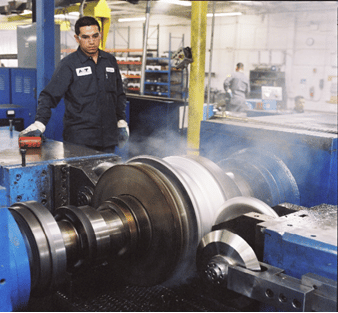

Superior Machine Shop Capabilities

Conventional and CNC machine shop with over 60 machines for lathe turning and milling up to 90” diameter and 80” length.

What We Offer for Metal Forming

Flow Forming

- Flow forming is a technique where a tubular preform is formed over a mandrel by rollers applying pressure.

- Advantageous for manufacturing tubular components to achieve reduction in wall thickness.

Metal Spinning

- Metal spinning takes a preform and clamps it against a spinning chuck. Spinning rollers form the preform until the material has been brought into final form and the surface is smoothed.

- Advantages include cost and materials savings, flexibility in creating any kind of form changes at a low tool cost in fast production runs.

Rotary Forging

- Rotary forging uses a combination of two actions, rotational and axial compression movement, for precise component forming.

- Enables greater use of materials, minimizing or eliminating machining and welding operations, in some cases.

- Benefits include shorter cycle times, better mechanical properties from superior working of material and high material utilization.

FAQ's

Forgings for the automotive aftermarket, space and aerospace industries.

Aluminum, copper, Inconel, titanium, steel and others.

Yes, most forgings are based on our customers specific requirements.

We have plenty of open capacity.

Yes, many staff members with years of forging experience.

Yes, we can meet very demanding specifications

Yes.

We do heat treating in house, finishing services are outsourced.

Potential customers are welcome to visit in order see our processes.

We have many customers who have been ordering for over 15 years.

Axially symmetric parts.