Propelling the future of space exploration with performance and precision – Our advanced metal forming processes deliver superior material efficiency and stronger rocket components, at a cost savings. Whether you need one-piece solutions, larger parts, complex geometries or anything in between – we’re here to support your project.

Industry-Leading, Metal Formed Rocket Components

Helping You Engineer the Components You Need to Make Your Space Launch Operation a Success; from Concept to Orbit

No matter what size, shape or state of assembly your project requires – we have the in-house technology and engineering know-how to ensure the ideal fit with your process.

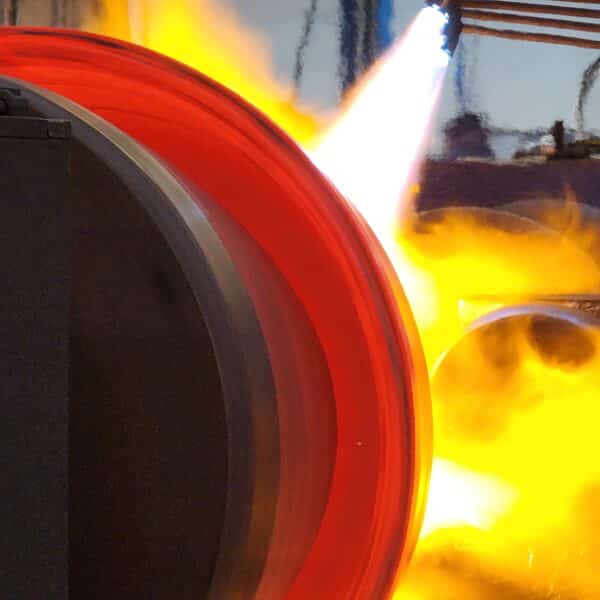

Combustion Chambers

Precision-Engineered, One-piece Combustion Chamber Liners and Jackets

One-piece combustion chamber liners and jackets with no welds require fewer post processes, which equates to lower cost, and higher efficiency.

AST currently supplies chamber liners and jackets for several rocket programs. We are confident we can efficiently produce your copper, or other material, combustion chamber liner to meet your specifications for the fastest delivery possible.

Cones and Nozzles

One-piece Nozzle liners and nozzle components – metal spun for optimized grain structure

Nozzle liners in copper, and cones, nozzle extensions and jackets in Inconel, Haynes, titanium stainless and more. We have the experience and capability to turn your specifications into a final part for your space program.

Fuel System Components

Flow formed tubes, spun formed downcomers and hatches.

AST works in 2219, 6061, 7075 and other aluminum alloys to produce customer specific components.

Flow formed inner and outer tubes range from 8” to 24” in diameter and from below 5’ to 15′ in length (feature dependent).

Spun formed components out to 110” in diameter and up to 200” in length.

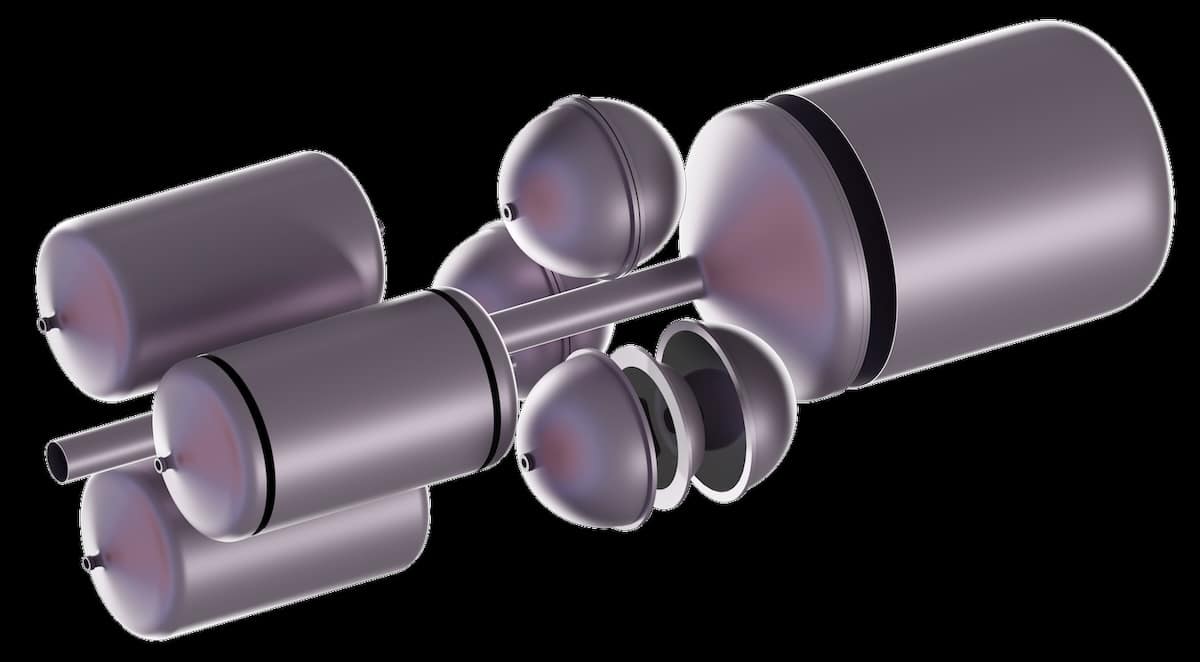

Pressure Vessel Components

Pressure Vessel Components designed to fit your production needs – cylinders, liners, tubes, domes, and more

Custom seamless pressure vessels and COPV liners in aluminum; or single seam liners in titanium, Inconel®, stainless steel or Haynes. We offer closed vessels up to Ø23” ID and vessel halves in various diameters from 8” to 50”; lengths up to 10’, and neck sizes from 1.5-5.5”, wall thicknesses from .03”-1”. All customized to meet customer specifications.

Solid Rocket Motor Cases

Solid Rocket and Hybrid Solid Motor cases, rotary forged and flow formed for optimal structural support to ensure maximum strength and performance.

Our in-house capabilities of rotary forging and flow forming of rocket motor cases gives our customers superior strength and quality products with manufacturing flexibility and faster delivery.

Why Choose AST for Your Aerospace Components?

In-House Versatility

Access to metal spinning, rotary forging, and flow forming capabilities – all under one roof provides you the flexibility to produce components of any shape, size or state of assembly based on your project needs.

One-Piece Specialization

Reduce material waste and post-processing expenses with no weld, seamless flight components that maintain quality and structural integrity at any size or shape.

Near Net Shapes

Optimizing material utilization, minimizing waste, and maximizing cost-efficiency for you are our key objectives.

Complex Geometries

We employ non-standard shapes for larger, lighter constructions. These are delivered as one-piece for heightened strength, durability, and performance.

Rotationally Symmetric Shapes

Our spinning machines can create a wide variety of rotationally symmetric shapes with a high degree of material efficiency.

Large Diameters

Our focus on large-diameter components provides scalability and strength. We can produce parts that are larger than 80” diameter and greater than 100” in length.

Near Net Shapes

CNC rotary forging presses offer near net shape forgings up to 56” diameter.

Rotationally Symmetric Shapes

Spin/flow forming machines, creating a wide variety of rotationally symmetric shapes with a high degree of material efficiency up to 60” diameter and 130” length.

Large Diameter Tubes

Our machines can create large diameter tubes and nozzles for high profile space applications, oversized military wheels up to 35” in diameter, and forged wheels up to 34” in.

Superior Machine Shop Capabilities

Conventional and CNC machine shop with over 60 machines for lathe turning and milling up to 90” diameter and 80” length.

AST Metal Forming Capabilities

As a customer, you don’t need to worry about the specifics. Just provide the specs you desire and our team will reverse-engineer the optimal process for you.

It’s our job to help you achieve the result you want – size, shape, metal properties, assembly considerations.. while factoring in your scheduling concerns and cost targets.

Our in-house capabilities ensure rapid, customized solutions for any shape—cone, tube, dome, or finished cylinder:

Benefits

- Greater dimensional accuracy

- Improved surface finish quality

- Material hardening

- Optimized grain structure

- Enhances material properties

- More load-bearing capacity

- Longer service life compared to components produced by metal cutting processes

How it Works

We leverage advanced manufacturing processes to forge metal combustion chambers and nozzles directly from a solid disk or ring.

With no welded sections, the resulting components boast increased structural integrity and require fewer manufacturing steps.

We clamp a preform against a spinning chuck.

Spinning rollers then gradually shape the preform, achieving the final form and smoothing the surface.

Rotary forging is a forging technology which uses a combination of two actions – rotational and axial compression movement, fore precise component forming.

It demands less force than traditional presses, enabling smaller presses and simpler tools.

Flow forming manufactures tubular components by applying pressure to a tubular pre-form over a mandrel using rollers.

The material rotates and is stressed to flow axially, achieving reduced wall thickness.

Our Rocket Component Consultation Process – Your Next Steps

- Provide your desired part specifications: including size, shape, performance requirements, and assembly considerations.

- Our expert advises you on the feasibility of the request and adjustments are made if necessary.

- Multiple drawings and design ideas are shared, and our expert provides insights on what can be achieved.

- You can decide on the best option for you based on price, speed and performance.

- We collaborate together to create your parts and keep you in the loop every step of the way.