Rotary forging is a specialized process that uses both rotational and axial forces to shape metal with extreme precision.

Unlike conventional forging, where the material is simply compressed, rotary forging carefully controls the grain flow, significantly increasing the strength and durability of the component.

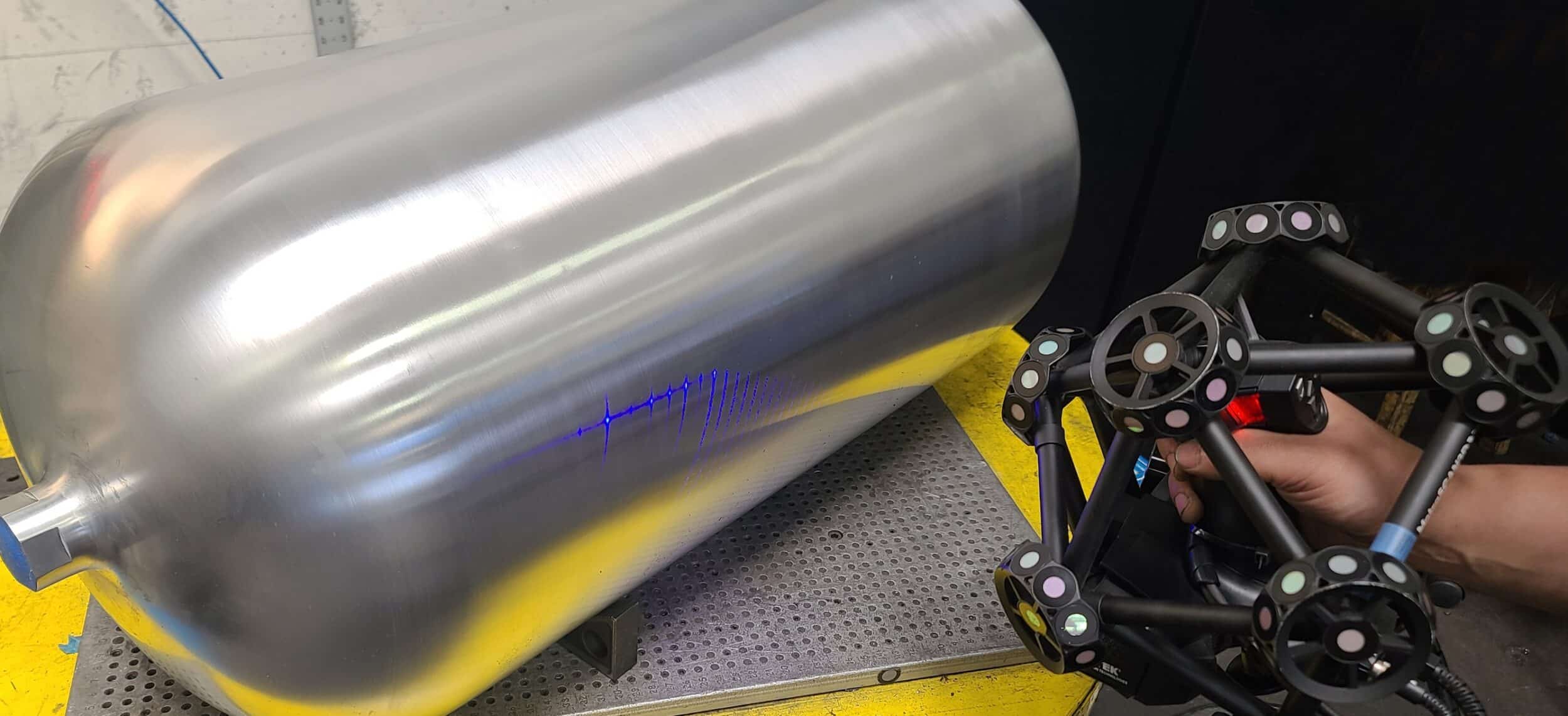

Rotary forging creates a strong, consistent base before moving to other critical steps of producing a seamless part; spinning, flow forming, heat treating, and machining.

This method is ideal for producing rocket “thrust” components like combustion chambers and motor cases, where both weight reduction and strength are critical.

With over 15 years of experience in rotary forging for space applications, AST stands apart as the only U.S. company offering rotary forging, flow forming, and metal spinning all under one roof.