Composite Overwrapped Pressure Vessels (COPV) [Ultimate Guide]

When circumstances call for large, lightweight, pressurized vessels for transporting fluids and gases, you need a storage vessel that’s safe, dependable, and has a long structural life. In these cases, your best bet is naturally a Composite Overwrapped Pressure Vessel (COPV). Safe and efficient pressurized vessels are an inherent need when launching into space or otherwise transporting potentially dangerous substances. Should a leak occur during these applications, obviously the results could be disastrous on a number of levels; for example, in the event of an explosion due to a leak, you risk the potential for loss of life, equipment, reputation, and financial resources.

For these reasons, the consequences of a COPV failure have reinforced the need for efficient and safe pressure vessels. The aerospace, alternative energy, and automotive sectors have all taken measures requiring testing and certification. When choosing the right COPV for your needs, you must consider the size, weight, price, potential points of failure, and the measures required to avoid (or minimize them).

This article intends to be the ultimate guide to help you understand the world of COPV’s and to help you make the best decision for the COPV applications you need.

What are Composite Overwrapped Pressure Vessels (COPV)?

Composite Overwrapped Pressure Vessels (COPVs) are lightweight storage vessels able to hold high pressures for pressurized gases and fluids. They have been utilized in the aerospace, alternative energy, and industrial automotive industries for many years. Commonly used for the storage of fluids for propellants in spacecraft and launch vehicles, they are also used for the storage of nitrogen and oxygen in environmental and life support systems.

Essentially, COPV’s consist of a non-structural internal liner inside a protective structural fiber composite outer shell. The internal liner creates a leak free barrier and separates the contents (fluids, hydrogen, compressed natural gas, etc) from the outer fiber composite, providing a barrier to prevent leaks and uphold the structural integrity of the vessel.

Composite Overwrapped Pressure Vessel Types

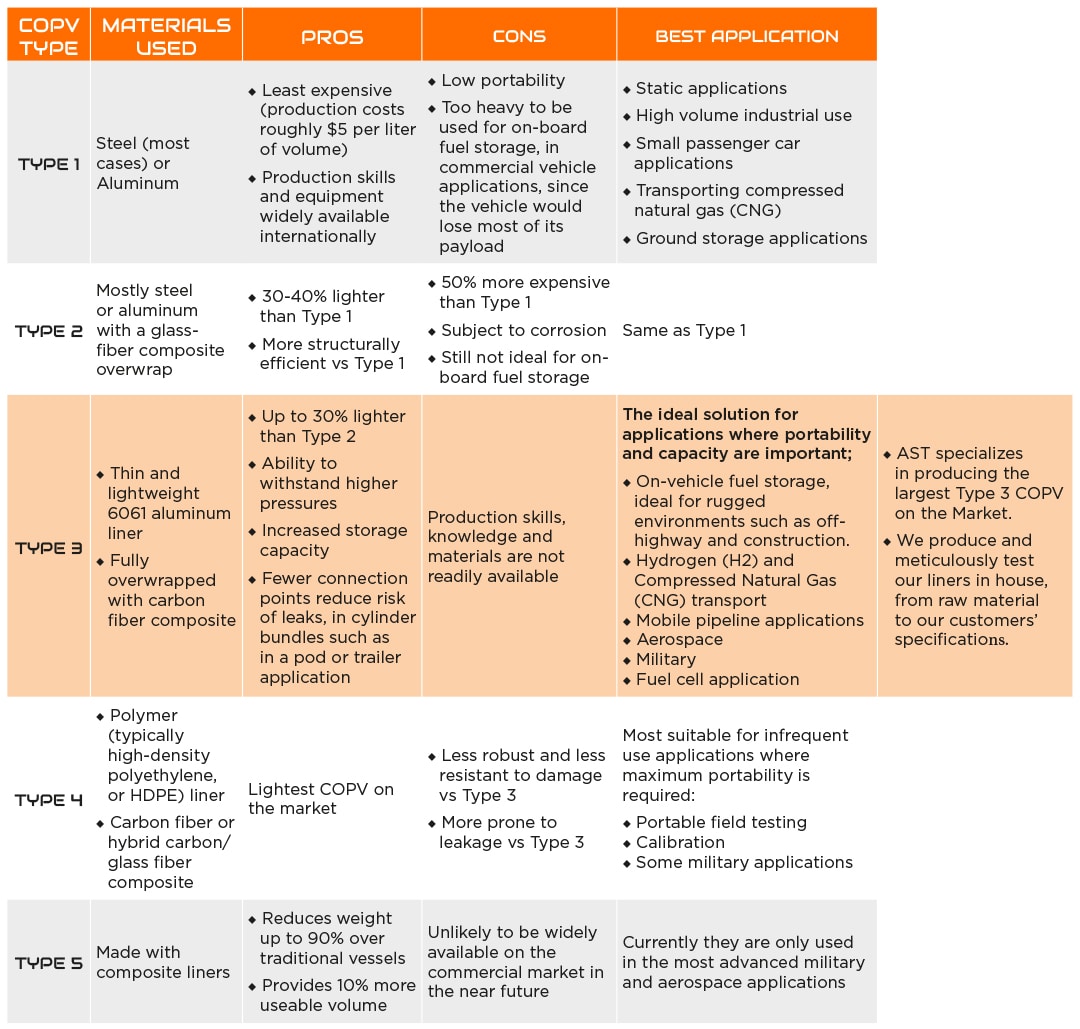

There are four main types of COPV’s that have been in use for years and a fifth type that’s fairly new. It’s important to understand what type of COPV you need as they are manufactured for specific applications.

COPV Types Comparison Chart

Type 1 COPV

Type 1 COPV’s are manufactured from all steel, or in some cases, aluminum. Type 1 all steel cylinders are too heavy to be used for on-board fuel storage in commercial vehicle applications since the vehicle would lose most of its payload. For this reason, Type 1 COPV’s are essentially only used in small passenger car applications, transporting compressed natural gas (CNG) or ground storage applications in general.

Typically, these are the least expensive of the COPV types, with estimated production costs of roughly $5 per liter of volume. Additionally, the metalworking skills and equipment needed to produce them are widely available internationally. Unfortunately, they are also the heaviest. This makes them most suitable for static applications and high-volume industrial use. They are less suitable for applications where low weights and portability is required.

Type 2 COPV

Type 2 COPV’s are mostly steel or aluminum with a glass-fiber composite overwrap. They have a thinner metal liner, a composite, and a wire or metal hoop “wrap” that provides reinforcement for the cylinders. This construction can reduce the tank load in the hoop direction, make hoop stress more nearly equal to the axial stress, while reducing the tank wall thickness and the weight of the tank, while also improving structural efficiency.

Type 2 vessels typically cost about 50 percent more to manufacture than Type I vessels, but they can weigh 30 to 40 percent less. That being said, they can still weigh in excess of 150-200 pounds. They are also subjected to corrosion.

Type 3 COPV

COPVs with advanced fibers and metal liners are classified as type 3 COPV’s. Type 3 COPV’s from Advanced Structural Technologies, Inc (AST), in particular, feature a thin and lightweight 6061 aluminum liner, fully overwrapped with carbon fiber composite. The composite materials carry the structural loads.

This specific manufacturing process for type 3 COPV’s offers a few benefits over the other types, including significant weight savings over Type 2 (up to 30%), as well as the ability to withstand higher pressures. This allows for increased storage capacity for the same size cylinder.

Another benefit for the customer with AST’s Type 3 COPV’s is that the large diameter and volume allows for fewer cylinders, valves, and PRDs. This directly minimizes potential leak points due to the reduced number of fittings and connection points required when compared to a traditional hydrogen storage system designed with smaller diameter cylinders.

Type 3 lightweight gas cylinders are ideal for applications where portability and capacity are important such as for home oxygen therapy and for medical oxygen cylinders in ambulances. They are also well suited for other applications such as Ambulatory oxygen, Portable fluid testing, Drone/UAV’s, Fuel cell applications, Aerospace and military, Calibration.

In fact, for on-vehicle fuel storage and most mobile pipeline applications, COPV’s either Type 3 (AST) or Type 4 are the only option. AST’s Type 3 COPVs are ideal to store and transport hydrogen (H2), Compressed Natural Gas (CNG), or other high-pressure gas.

AST differs from most other Type 3 manufacturers because of our capability to manufacture the largest diameter Type 3 in the market. A big reason we are able to do that is that we manufacture our liners from scratch in-house. This enables us to produce liners to our customers’ specifications. From there, the finished liner is then carbon fiber overwrapped, cured, autofrettaged, and hydrostatically tested prior to delivery to the customer.

There are definite advantages to larger COPV’s. The greater storage capacity of these seamless Type 3 COPVs results in longer intervals between refueling. They are damage tolerant and maintain gas impermeability throughout their service life.

Type 4 COPV

COPV’s with advanced fibers and polymeric liners are classified as type 4 COPV’s. Similar to a Type 3, Type 4 COPV’s include an all-composite construction featuring a polymer (typically high-density polyethylene, or HDPE) liner with carbon fiber or hybrid carbon/glass fiber composite. The composite materials carry all of the structural loads.

These are the lightest cylinders available on the market today. The key benefit of Type 4 cylinders is reduced low weight, which makes them most suitable for infrequent use applications where maximum portability is required. The downsides of Type 4 cylinders are that they are less robust and less resistant to damage. This is where the Type 3 COPV’s step in. In addition, the polymer lining does not provide an impermeable barrier, making them more prone to leakage.

Suitable applications include portable field testing, calibration, and military applications.

Type 5 COPV

These are not widely available yet. Type 5 COPV’s are made with composite liners. The next generation of gas cylinders, currently they are only used in the most advanced military and aerospace applications. They are unlikely to be widely available on the commercial market for a few years. A liner-less all-composite vessel, a type 5 COPV provides 10% more useable volume while reducing weight by 90% compared to traditional vessels.

COPV Tanks

When it comes to choosing which tank is best for the application you need, it’s important to consider a few factors. For example, most who come to us are concerned with price, weight, pressure capacity, and then of course, availability, or lead time. These are critical factors in choosing not only which tank is best for your needs, but also in which manufacturer to work with. Some manufacturers may not fit your timeline, or be able to work with you to manufacture the solution that will best fit your needs. This is important because, as we covered above, there are definitely differences in weight, applications, and manufacturing styles.

The best way to avoid delays in lead time, and to choose the right COPV type and manufacturing process for your needs, is to speak with the experts at the manufacturing company you’re considering working with. They will be able to guide you to choose the right option for your application, explain their manufacturing process, and discuss their lead times and customization capabilities.

Pressure capability is very important for the safety and efficiency of a COPV tank. You need to know the burst pressure, as well as the possible failure points – and how to avoid them. Keep reading to learn the specifics on that below.

COPV Design & Manufacturing Process

Does the design affect your purchasing decision? Absolutely.

Let’s follow AST’s process for a Type 3 COPV:

The COPV Design Process

Let’s start from the beginning. We’ll take a look at the tubes used to create the liner. Advanced Structural Technologies, Inc manufactures the tube used to create the aluminum liner, this allows us to make any size the customer wants.

Here are the steps to manufacture a Type 3 COPV:

- Manufacture the tubes to create the liner. Most manufacturers make them from extruded tubes whereas AST makes them from forged blanks which are stronger. This is a huge benefit because when you start with forgings that are stronger than extruded product from overseas, you can manufacture larger diameters than most flowforming facilities , and make them the exact diameter the customer wants. AST can manufacture forge and spin tooling for any diameter and lengths of up to 120 inches. Most other suppliers are constrained by the availability of a tube of the correct diameter and thickness to build the liner.

- Build the liner. Type 3 COPV’s use 6061 aluminum forged liners in most cases. 6061 is an easy alloy to forge and flowform and does a great job of containing gases, for example, in space applications such as helium storage.

- Spinning the liner. That forging is then spun into the closed, seamless liner using three different spinning operations.

- Heat treat the liner. The parts are then heat treated to a T-6 condition.

- Machine the neck. Next, we machine the internal and external threads needed for valve and cylinder installation.

- Wrap the liner. The liner is then wrapped in a carbon fiber/resin composite and the resin is cured.

- Testing. Finally, each piece is autofrettaged and hydrostatically tested and labeled for shipment.

Composite Overwrapped Pressure Vessel Materials

Ok, now that we’ve discussed the process, let’s take a look at the materials used. It’s important to choose COPV liners that are compatible with the compounds that will be stored. We’ve mentioned some of them already:

6061 aluminum-liner

6061 Aluminum is used because it’s in a thickness sufficient to act as a chemical barrier and as a mandrel for winding, rather than as a structural component. 6061 is also available to source at a reasonable price. Benefits of 6061 aluminum liner include an important strength: density. “With a density of 0.0975 lb/in3 aluminum offers high specific strength, unmatched by stainless steel. Aluminum offers the benefit of potentially substantial weight savings compared to stainless steel.” (Source)

Steel

There are three stainless steel alloys that are appropriate for COPV liners – mostly for type 1 and 2 COPV’s. Stainless steel is highly processable, easily weldable, and easily machinable. With a density of 0.289 lb/in3 stainless steel is close to three times as heavy as aluminum per unit volume.

Carbon Composite Fiber

This is extremely strong and used for the outer wrap of the COPV. It can be expensive to produce, but is commonly used wherever high strength-to-weight ratio and stiffness (rigidity) are required. (Source.)

Titanium-Lined Carbon Composite Pressure Vessel

Another we haven’t mentioned is a titanium-lined carbon composite overwrapped pressure vehicle. According to research from Aerospace Research Central, these are unique vessels with the liner and end fittings fabricated in pure titanium, the COPV has the added benefit of higher resistance to corrosion and oxidation, good low-cycle fatigue characteristics (good for pressure cycling), good high-cycle fatigue characteristics (good for environmental testing), as well as being easily weldable (reducing manufacturing costs).

Composite Overwrapped Pressure Vessel Explosions

As safety is a primary concern, each sector has its own COPV testing standards. For example, the aerospace sector follows standards developed by the AIAA, establishes performance-based requirements verified through a combination of analyses and tests. The automotive sector has developed prescriptive requirements through the CGA and ISO. Safety and high reliability don’t end with testing, however; they are achieved by adhering to rigorous processes throughout the life cycle of a pressure vessel, including the design, manufacture, testing, handling, and operation phases.

At AST, we conduct burst tests to ensure the utmost safety for our customers. Once design validation is complete for each lot of cylinders, which is no more than 200 pieces, a Hydraulic Burst and Ambient Cycle test must be successfully completed.

Here’s a check-list of what our design validation tests include:

Preventing COPV Failure

While we are confident in our testing, as mentioned, it’s just one essential part of ensuring safety throughout the product life cycle. Unfortunately, one of the primary causes of explosion or failure for COPV’s is improper handling, usually after the COPV’s leave the manufacturing plant and are in the hands of a customer.

The good news is that if the COPV is treated with the manufacturer’s recommended care and is not over-pressurized, exposed to extreme temperatures due to malfunctioning fueling equipment, or impacted in an accident, the COPV can safely be used for the maximum duration allowed by law (20 years for CNG and 15 years for hydrogen applications).

Manufacturer’s recommendations notwithstanding, the primary points of failure, if they do occur would be leaks in the port, leaks in the liner, or a liner burst.

To best avoid this, careful machining of the port is required as well as following safety guidelines. Additionally, consider both the quality and the size of your COPV’s. A larger size COPV directly reduces the points of failure by reducing the number of fittings and connection points as compared to conventional cylinders. The greater storage capacity also allows for longer intervals between refueling, resulting in less wear and tear on the COPV and its fittings.

COPV Applications

AST provides COPV’s for many types of high pressure gas storage applications. Customization usually translates into custom COPV dimensions suited to fit a particular customer’s space constraints and/or application needs.

We can supply customers who have a requirement for a large diameter COPV’s.

COPV for Aerospace

For over 5 years, AST has manufactured and delivered COPV components such as large hemispheric domes, tubes, liners, and COPVs to rocket manufacturers all over the world.

We have the ability to customize to our customers’ specifications. Give us a call to discuss your needs.

COPV for Alternative Energy Storage

AST has been producing COPV components such as CNG liners for alternative energy applications since 2008. With hydrogen being discussed as the next clean energy for fuel, especially in light of the recent Bipartisan Infrastructure Framework (BIF) signed by the President, AST’s Type 3 cylinders offer key benefits for hydrogen storage and transport.

AST’s Type 3 cylinders offer advantages for compressed gas applications where safety and enduring impermeability are paramount, such as in alternative energy transport. For optimal safety and storage potential, large pressure vessels are required, and with our own unique flow-formed forged liner technology, the COPV’s can exceed the performance of extruded tube methods.

Additionally, often in alternative energy applications, customers need hydrogen COPV’s that are uniquely suited for rugged environments, and ideal for compressed cryogenic applications.

Advanced Structural Technologies, Inc. Reliable Composite Overwrapped Pressure Vessel Manufacturers

If you have an application that requires larger diameter tanks, AST specializes in high capacity, high-pressure storage solutions up to 27” (69 cm) diameter and 120” (305 cm) in length. We also support smaller, more traditionally sized COPV applications.

Our Type 3 COPV’s are an excellent choice for hydrogen transportation, Hydrogen Fuel Cell (HFC) applications, marine, rail and rugged mine applications, where the advantages of a Type 3 are particularly well suited.

Additionally, AST can provide whatever you need for your Type 3 application, whether that’s a tube to be finished into a liner, a finished liner to be wrapped for a COPV, or a completed COPV.

Advantages of Our Type 3 COPV’s:

- Largest diameter Type 3 cylinder for hydrogen applications in the market because our custom cylinder diameters are fabricated in-house

- A seamless, one-piece aluminum liner provides:

- Inherent leak before burst failure mode

- Superior heat tolerance for extended cylinder life

- And higher impact tolerance for increased safety

- Faster and complete filling with significant benefits

- Efficient and complete fills in extreme temperatures

- Reduced fueling costs as superior heat dissipation requires no chilling during the filling process

- More complete fueling reduces range anxiety

- Extended-life cylinders

- No replacement is needed after exposure to high temperatures

- DOT approval for maximum cylinder life

If you have a need for COPV’s, talk to the experts at Advanced Structural Technologies to find the best solution for your specific application.

Book a call with us today.