AST’s in-house flow forming process ensures precision, superior mechanical properties, and optimized material usage.

With every stage handled under one roof, we deliver your critical components faster, with unmatched reliability and cost-efficiency.

AST’s in-house flow forming process ensures precision, superior mechanical properties, and optimized material usage.

With every stage handled under one roof, we deliver your critical components faster, with unmatched reliability and cost-efficiency.

Relying on multiple suppliers for metal forming and machining adds delays and risks to your timeline.

Conventional methods can lead to unnecessary material usage, increasing costs and inefficiencies.

Leaks, failed tests, and subpar specifications are common when flow forming is not used or poorly executed.

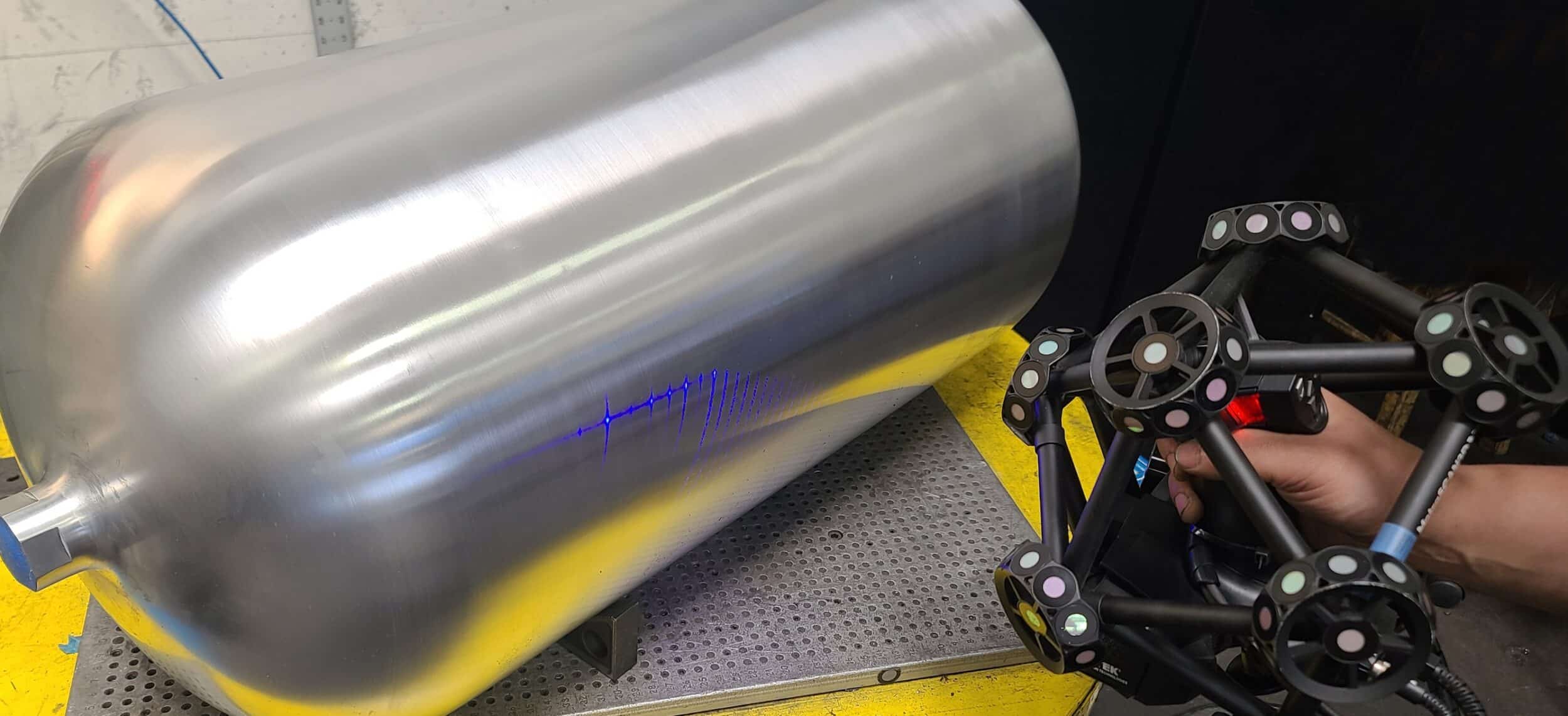

Flow forming is a specialized metal-forming process where tubular components are formed over a mandrel using precise, controlled rollers. This method reduces wall thickness uniformly while maintaining superior strength and durability.

Ideal for rocket motor cases, pressure vessels, and other critical components, flow forming minimizes waste, enhances strength-to-weight ratios, and delivers unmatched accuracy for applications in both space and defense industries.

When improperly substituted with alternative processes, critical specifications are often missed. AST ensures precise execution of flow forming to meet your project’s exact requirements.

Check out our full guide on flow forming for more detail.

Our Flow Forming Process Delivers Stronger, More Reliable Components with Reduced Costs, Faster Timelines, and Industry-Leading Size Capabilities.

AST is the only U.S. provider that offers rotary forging, flow forming, and metal spinning, all under one roof.

You need all three—rotary forging for initial shaping, flow forming for tubular strength, and metal spinning for conical precision. Our all-in-one solution eliminates the need for multiple suppliers and shortens your lead times.

We focus on minimizing material waste to lower your costs.

Eliminate the excess material usage and unnecessary costs that result from alternative, conventional processes.

We produce the strongest, largest and most reliable components in the industry.

Get seamless, precision-engineered components with unmatched strength, durability and size that meet even the most rigorous testing requirements.

Flow forming delivers unmatched advantages for building high-performance tube components and meeting the extreme demands of the space and defense industries. Here’s why:

| 1. Longer Service Life | Seamless construction reduces weak points, enhancing component durability and longevity. |

| 2. Higher Load-Bearing Capacity | Precision-forming improves material performance, enabling components to handle extreme forces. |

| 3. Unmatched Accuracy | Achieve precise wall thickness and dimensions for critical applications. |

| 4. Versatility Across Applications | From rocket motor cases for space launches to pressure vessels for hypersonic missile systems, AST delivers components that excel in extreme conditions. |

| 5. Cost Efficiency | Optimized material usage and an all-in-one process reduce waste and overall expenses. |

Our state-of-the-art flow forming machines are capable of producing the largest diameter metal tubes in the industry, setting AST apart as the go-to partner for complex, high-demand projects.

AST operates as an ISO-certified flow forming provider, ensuring every component meets stringent quality standards.

From initial consultation to final testing, we work closely with you to select the best process for your needs—whether it’s rotary forging, flow forming, or metal spinning.

By keeping everything in-house, we maintain complete control over quality and lead times, ensuring your project stays on schedule and meets the most stringent specifications.

You provide specifications: size, shape, requirements.

Your AST manufacturing expert Assesses project feasibility and potential challenges.

We share designs and your expert advice on ideal outcomes.

Compare the flow forming process to other options on cost, speed and performance.

Once we determine advanced metal spinning is the ideal process for you.. We kick off the project!

Ready to streamline your production and elevate your components? Contact AST today to discuss how our flow forming services can meet your space and defense needs. Our expert team is ready to deliver components that exceed expectations—on time and within budget.

In the space/aerospace market, typically aluminum is most commonly form formed, but you can also form steel and other exotic alloys.

Contact us to give us information on the project.

In the space/aerospace market, typically aluminum is most commonly form formed, but you can also form steel and other exotic alloys.

Flow forming is typically used in space and aerospace applications. We also flow form liners/cylinders in the alternative energy market for hydrogen storage.

Flow forming is a transforming process that a metal plate or cup-shaped metal workpiece is rotated over a mandrel while a roller deforms the workpiece, forcing it against the mandrel. The process allows you to stretch the material thinly, thicken it, or cleave and expand it as if working with dough.