Open Die Forging vs Closed Die Forging

Forging is the oldest metalworking process in the world. You might say it’s ancient, but with today’s modern technology, and new processes, forging offers new benefits. Like strength and durability. There’s more than meets the eye though. When it comes to safety, and reliability, especially for products used under stress and at pressure points in machinery, you want a forged product that meets the highest standards.

This article discusses two types of forging processes: open die forging (the more conventional process) and closed die forging, including non-conventional closed die processes like “rotary forging” that offer greater dimensional accuracy, better surface finish quality, strength, and grain flow. Keep reading to discover:

- The difference between open, closed die, and rotary forging

- The benefits of each, explaining the surge in demand for rotary forging, especially for components with large and complex geometries.

- Which applications are best for each

- How the processes determine different qualities in a product

- Factors to look for when choosing a forging process and company to work with

Let’s dive in…

What Is Open Die Forging

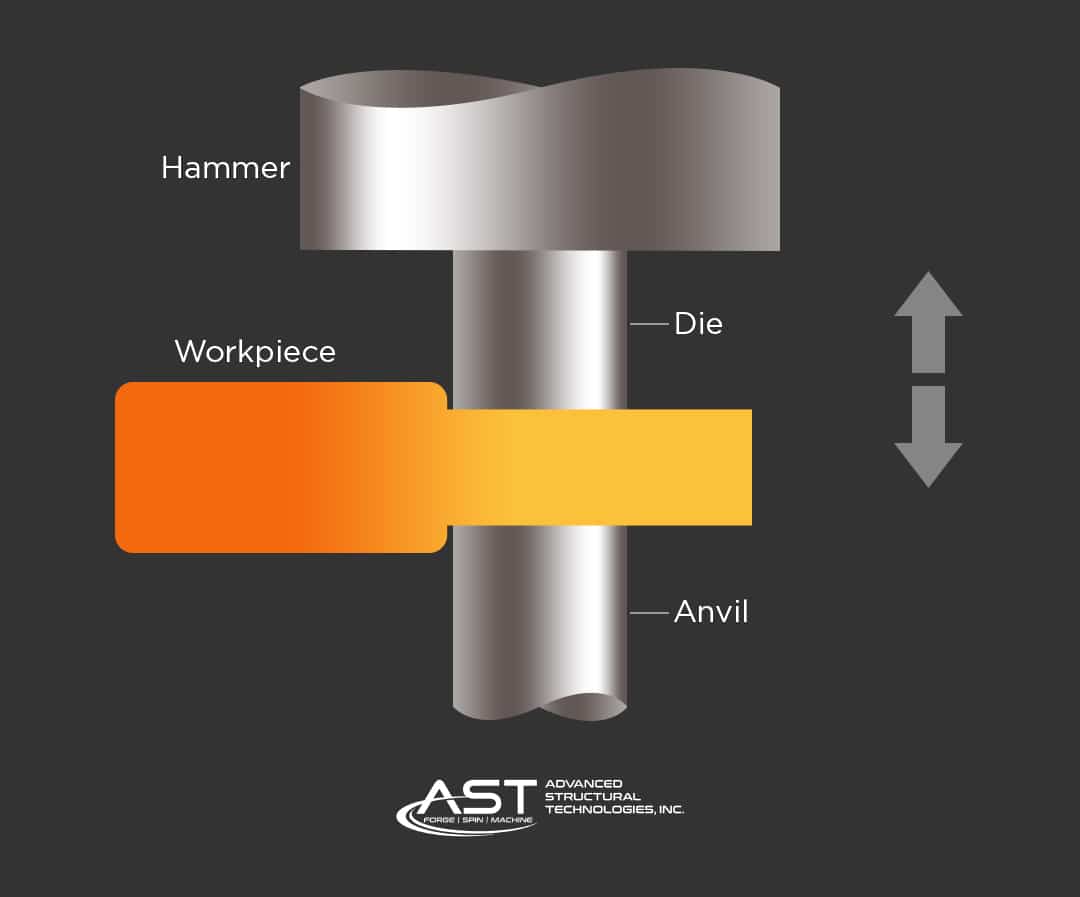

A method of forging, open die forging is probably what most think of when they bring to mind a traditional blacksmith; you’ve got heated metal being hammered on top of an anvil to shape it into something brand new. This is also called free forging, or smith forging. A variation on openly hammering and shaping metal, is to put the metal between two dies where the metal is compressed, or repeatedly “hammered” under great pressure. The two dies compress the heated metal billet and shape it.

It’s the dies that separate open die forging from closed die forging. With “open” dies, the part of the die that compresses the metal is typically flat, or slightly contoured so that the metal is compressed between the two surfaces. Other variations of open die forging, the dies can be curved, or even V-shaped, but the metal is never fully encased within the dies.

Open die forging process

It’s a straightforward process:

- You take a metal billet, or starting stock, measured by weight, heated to extreme temperatures (1900-2300 degrees Fahrenheit).

- Lay it in between the dies in the direction of the grain in order to maintain structural integrity throughout the open die process.

- A “fuller” tool divides the metal piece into sections, marking which section to work on at a time.

- The dies compress the metal, or “hammer” it into shape as the metal adapts to the pressure.

The main advantage of open die forging is that at a structural level the grain flow of the metal is actually strengthened, refined, and contoured as it is exposed to repeated pressure. This reduces porosity and improves the strength, durability, and fatigue resistance of the final product.

Additionally, open forged dies allow for varied customization, though generally in still fairly simple shapes. It also provides a quick lead time, with little to no extra tooling costs, and because it uses material more efficiently than machining or cutting metal, open die forging reduces material costs.

What is aspect ratio in open die forging

In its simplest form, an aspect ratio describes the width of an image in relation to its height. In open die forging, aspect ratio is important to the final product because it will determine the amount of pressure, and the shape of the die needed in order to realize the final shape.

It’s actually a key measurement taken for each pass of the “hammer” to understand how the metal is changing shape, or deforming. The dies’ shape is another key factor in how well open die forging is executed.

In other words, a metal billet that starts out with a height to width ratio where there is a lot of height that needs to be reduced in order to reach the final shape will need a different process (or at least longer process) than a billet with a smaller aspect ratio.

What is barreling in open die forging

Barreling is when the metal billet starts to form a barrel shape as it’s being compressed in an open die forging process. It’s caused primarily by frictional forces at the surface of the die that prevent the surface of the metal piece from expanding, even though the center of the metal piece expands. This creates a “barrel” shape where the metal piece curves inward at the top and at the bottom of the shape. In this case, lubrication would reduce the friction at the surface of the die and allow the metal piece to expand evenly throughout.

Another reason for barreling is that at the surface of the die, the metal piece can cool more rapidly than in its center. Again, this causes the top and bottom of the metal piece to expand at a different rate than the center. Heating the dies in this case would reduce the barreling effect.

Open die forging applications and types

Open die forging is used for both large high strength metal pieces, and smaller items where strength is required. The process provides extra durability and strength and is very efficient for applications where human well-being and safety is involved. For example, the Aerospace, Military, Alternative energy, Automotive industries often rely on open die forging.

While there are many types of open die forging applications and types, the open die forging process is best for products lacking complexity that fall into four shape categories:

- Cylindrical Shapes

- Upset or “Pancake” Shapes

- Hollow Forgings

- And Contour-type forging.

Products in those categories could include things like discs, rings, sleeves, cylinders and shafts, step shafts, bars, beams, spindles, hubs, mandrels, metal shells, simple pancake forgings, pierced blanks and more.

This forging process can also be used for large products, even up to 80 feet long and over 100 tons.

Cylindrical Shape Forgings

Cylindrical shape forgings are used in a variety of industries that need extremely strong and durable products. For example, the aerospace industry uses open die forging for things like rotor/propeller parts, landing gear components, flat bars, etc.

The Automotive and the Military industries also use forged parts. Their strength, reliability and economy make them an obvious choice for vital automotive and truck applications as the uses are generally required for points of shock and stress. Some of these applications include wheel spindles, kingpins, axle beams and shafts, torsion bars, ball studs, idler arms, pitman arms and steering arms, connecting rods, as well as transmission shafts and gears.

Upset or pancake forgings

“Pancake” forgings are disc-like, similar to a pancake. These applications include things like discs, hubs, hubs, flats, hexes, rounds, and plates. These products are used reliably in the industrial, aerospace, military industries to bring safety to commercial jets, helicopters, piston-engine planes, military aircraft and spacecraft.

Upset forging involves locally heating a metal bar and then applying pressure to one end of the bar. The result is a long item with a forged ending. Upset forging produces elongated parts such as shafts, screws, piston rods and others for the automotive industry, public works, aerospace and other industries.

Hollow forgings

Hollow forging using the open die process produces products such as large hollow tubes. They can be straight, hollow cylinders, or tapered hollow shapes as well. With open die forging, you can also customize the width of the walls.

As the tube is forged, rather than having a hole bored out, it holds up better for stressful applications. This same process can be used for tubes, rings, seamless rolled rings (bearings), shafts, and more. Again, due to the strength gained through open die forging industries such as Aerospace, Military, Alternative Energy, Automotive and more use these parts to support their applications.

Contour-type forgings

Contour-type forgings are great for ring rolling applications where some contour to the dies are needed.

Due to being strong, and cost-effective, rolled rings are used for many applications, from jet engines, jet turbines, windmills, paper mills, helicopter gearboxes, and machinery exposed to stressful environments.

Closed die forging

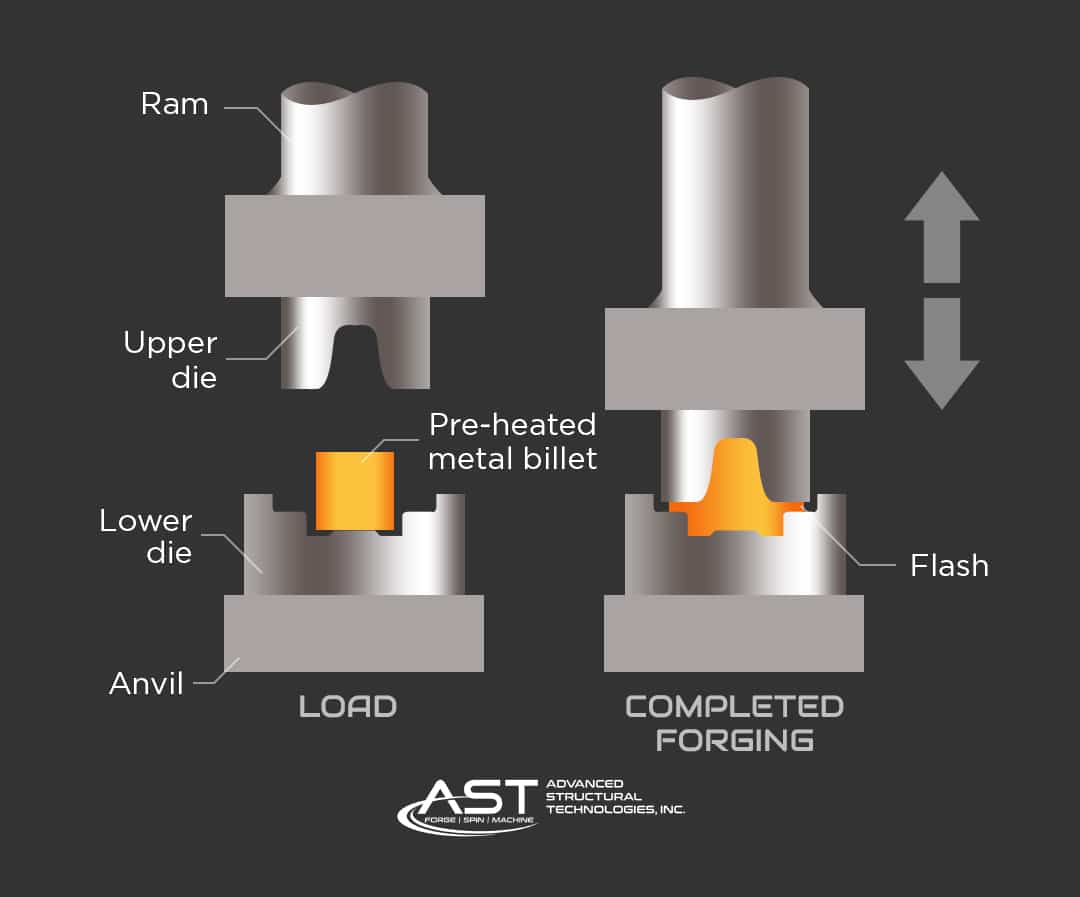

Also called impression forging, closed die forging is very similar to open die forging, except that the dies are custom made in specific shapes and the metal is encased within the dies.

Open die forging uses dies that leave the metal open, but closed die forging encases the metal, allowing for more precise forged shapes:

- Prepare your pre-form or metal billet.

- Heat the metal and exert pressure by “stamping” or “hammering”, similar to the open die process.

- The metal will fill the space inside the dies. What little metal comes out between is called the “flash” and only helps to put more pressure to create the shape.

- Remove the flash and prepare the new shape for its end use.

Closed die forging applications

Closed-die forging is one of the most commonly used methods for forging steel parts. Like open die forging, it is also strong and durable, having worked the metal’s internal grain structure. Well suited to produce parts that are smaller in size and in large quantities, closed die forging is great for parts that do not have complex mechanical properties.

Examples of closed die forged applications for the automotive industry include connecting rods, Control arms, Axle beams, Axle shafts and more. For the industrial sector, expect to see gears, shafts, hammer union nuts, spike harrow teeth, tie rod ends, shackles, hooks, and more. Of course there are endless applications for the military and aerospace, alternative energy industries as well.

What is the difference between closed die forging & open die forging

To summarize, open die forging differs in its process from closed die forging (impression forging) by the shape of the dies used. Typically, open dies are flat, possibly concave or v shaped, but always open. Closed die forging on the other hand uses dies that completely encase the metal, allowing it to fill up the space between the dies.

While both processes are similar and produce strong products as the grain flow is worked and follows the shape of the metal, open die forging is typically reserved for short or long production runs, simple shapes in general, and in varying size (from small shapes to large 80 foot, 100+ ton beams and tubes). Closed die forging uses customized dies and therefore is more suited to producing more specifically shaped products for longer runs.

Rotary Forging – A Unique Die Method

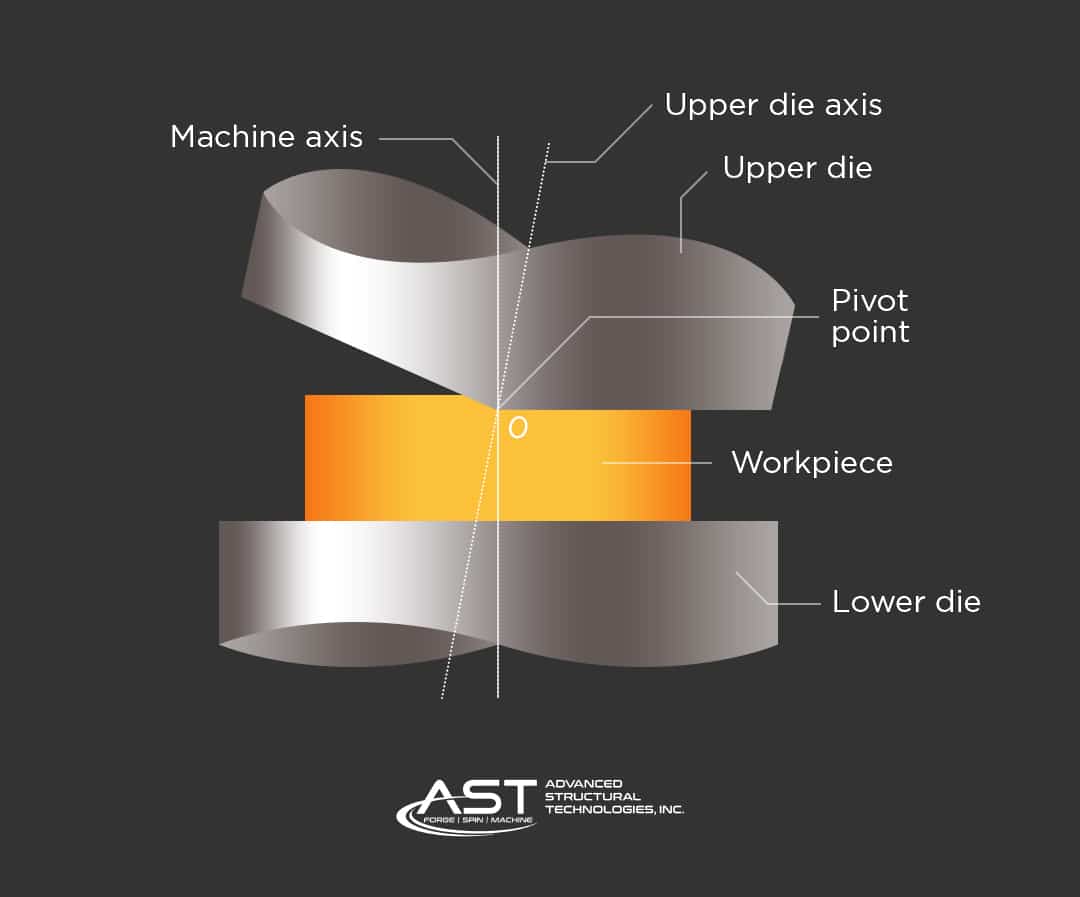

Modern manufacturing requirements demand short lead times and cost effective flexible production. While the concept of open die and even closed die forging has been used since the first metalworking attempts, there is a new method that’s gained popularity in the last few decades that enables manufacturers to meet those requirements. Due to its non-conventional but ingenious method, rotary forging is a closed die forging process that angles a contoured or conical die to apply pressure and deform the metal from pre-form to a finished product with more accuracy, less time, and increased cost efficiency.

While the conventional open die process uses two stationary, parallel, flat dies, rotary forging employs a combo of rotation, rolling and axial compression with dies that are neither parallel nor flat. This translates into compression in a more concentrated area while delivering superior structural integrity and grain flow in the metal.

More specifically, rotary forging offers greater dimensional accuracy, better surface finish quality and material hardening, and optimized grain structure.

Another major reason for consideration is that the concentrated compression enables manufacturers to form net- or near-net-shape components (whereas with conventional forging, you’d likely pay high prices only to machine up to 95% of it away as waste).

Rotary Forging Applications

It’s no surprise that approximately one-quarter to one-third of all parts that are either hammer or press forged could be formed on a rotary forge. The benefits have attracted attention from the automotive, aerospace, and alternative energy industries.

Rotary forging is particularly good for those who require components with large and complex geometries. The process produces products that require ring rolling, spinning/flow forming, swaging and cross-wedge rolling, or more complex shaping. In fact, it’s often for parts that would otherwise have to be completely machined because of their shape or dimensions.

Particularly effective in forging parts with high diameter-to-thickness ratios, rotary forging is ideally suited to this process because of its ability to concentrate its compression. Applications of rotary forging include gears, flanges, hubs, cams, rings, and tapered rollers, as well as thin disks and flat shapes. Changing the type of motion of the die, allows for other applications including T-flanges, thin disks and large flanges.

Rotary forging is also used to produce intricate features on workpiece surfaces. Parts such as gears, hubs, and hexagonal shapes have traditionally been difficult to produce by conventional forging because die-workpiece friction made it difficult to fill tight spots properly on the dies.

Rotary Forging Company

Picking a rotary forging company to work with can be tricky because of the many options that exist. A few things you’ll want to consider is the company’s experience, ability to work with you to achieve your goals on your timetable, and when it comes to forging, how the process reflects the final quality. Even in open die forging, there are different approaches.

For example, with Advanced Structural Technologies (AST), we’re ideally suited for rotary forging and known for our superior grain flow. Our process forges in a contoured die, vs flat parts without contour. This allows for uniquely strong and reliable products.

As for experience, with over 20 years refining our metal forming processes, we’ve gratefully become a world leader in providing forged products for the space/aerospace, military, and alternative energy industries, as well as a well known provider of forged wheels for the automotive aftermarket.

Known for our expertise in forging complex, single-piece shapes, AST products are used by world-renowned companies for their various applications.

Our experience and our process allow us to innovate and maintain the top quality and excellence that our customers have come to know.

If you’re currently in need of metal working, let’s talk about your options. It’s worth taking the time to discover what advantage you’ll have with AST Forge and how we can help you meet your goals.