How to Store & Transport Hydrogen – The Ultimate Guide

In the quest for a greener, cleaner fuel source, hydrogen is receiving a lot of attention.

Hydrogen is a flexible and clean energy source that has the following abilities:

- It can power fuel cells in zero-emission vehicles

- It has no adverse environmental impact

- It can be produced locally

Did you know? The transportation sector is responsible for about 17% of greenhouse gas emissions from all human activities. Hydrogen has the potential to dramatically reduce these greenhouse gas emissions.

Reducing emissions from transportation is essential to achieving the United Nations Sustainable Development Goals and fulfilling the Paris Agreement.

The biggest hurdle to this achievement is the safe storage and transportation of hydrogen.

At Advanced Structural Technologies, we manufacture high-pressure Type 3 vessels for the storage and transport of compressed hydrogen.

Here, we’ll focus on the safe storage of hydrogen and explore the available options to give you a deeper understanding of the relative merits of each option.

Hydrogen Energy Storage

Hydrogen from renewable sources—such as wind, solar, hydro and geothermal sources—needs to be transported from the point of production to the point of use.

Over the years, the most preferred method of storing hydrogen has been in liquid form. It has always enabled hydrogen storage in larger volumes.

There has been a need, however, for safer methods of hydrogen storage that are also less costly. This has contributed to the introduction of other modes of storage and transportation.

For example, the storage tanks available today are lighter and able to hold more than those of a few years back.

For renewable energy, the ability to store large amounts at fueling stations offers a future of clean and flexible fuel.

If you’re a decision-maker in the industry or you’d like to set up a fueling station for your fleet, you need to have a deep understanding of the storage problems and solutions for hydrogen.

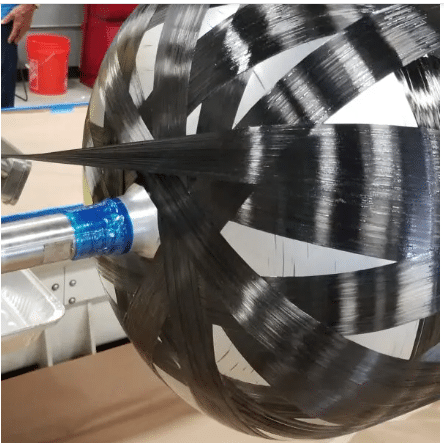

Alt: Type 3 hydrogen storage vessel

Hydrogen Storage Problems

The main challenge preventing a successful hydrogen economy is limited storage solutions. However, once a viable solution is in place, it’s ready to take off.

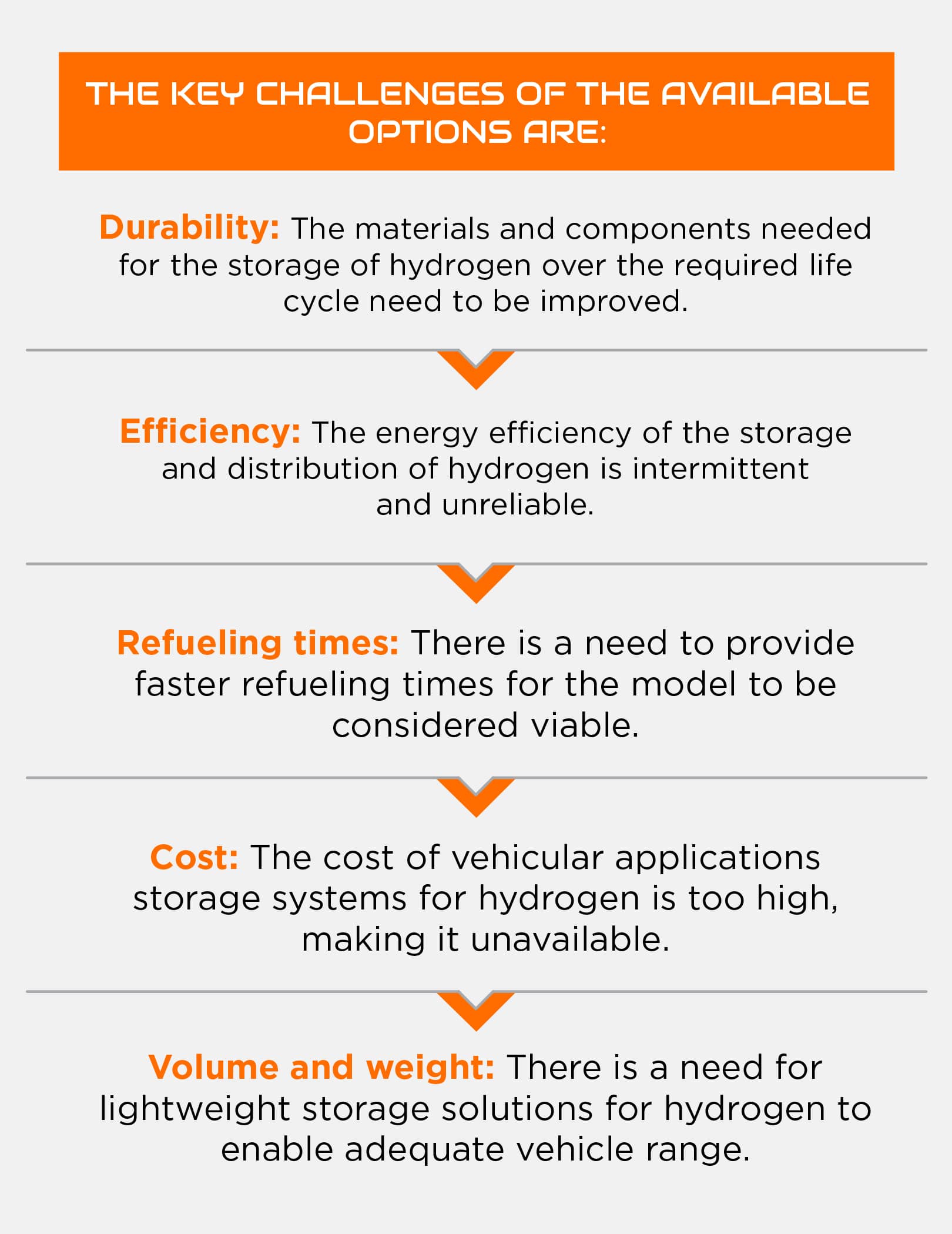

The key challenges of the available options are:

- Durability: The materials and components needed for the storage of hydrogen over the required life cycle need to be improved.

- Efficiency: The energy efficiency of the storage and distribution of hydrogen is intermittent and unreliable.

- Refueling times: There is a need to provide faster refueling times for the model to be considered viable.

- Cost: The cost of vehicular applications storage systems for hydrogen is too high, making it unavailable.

- Volume and weight: There is a need for lightweight storage solutions for hydrogen to enable adequate vehicle range.

However, with sustainable mobility solutions, all the above challenges can be eliminated to pave the way for a hydrogen economy.

Storage options that offer maximum safety with no risks of potential leaks can ensure the public acceptance of hydrogen as an alternative fuel source.

As challenging as it is to store hydrogen, there are various methods that can be embraced to provide a lasting and viable solution.

Hydrogen Storage Methods

There are four main methods of storing hydrogen:

- Compressed hydrogen storage

- Geological storage

- Liquified hydrogen storage

- Materials-based storage

We’ll now take a closer look at each of the methods.

Compressed Hydrogen

Compressed hydrogen is the gaseous state of hydrogen energy.

Here, hydrogen gas is tapped into a compressor inlet. It’s an intensive process that highly impacts the cost.

Hydrogen can then be stored in cylinders or gas tubes with pressures between 200 and 500 bar.

Compost overwrapped pressure vessels (COPVs) are the most preferred method for the storage of compressed hydrogen.

However, COPVs are lightweight and are more suitable for large-scale transportation and storage of hydrogen.

There are four types of COPVs:

- Type 1: Made of steel

- Type 2: Made of steel with a glass fiber or composite hoop overwrap

- Type 3: Made of a aluminum liner and fully wrapped in carbon fiber composite

- Type 4: Made of a polymer liner and fully wrapped in carbon fiber composite

- Type 5: linerless COPV fully wrapped in carbon fiber composite

Type 3 and Type 4 COPVs are considered the best and are mostly used to transport compressed hydrogen. This is due to their light weight, which enables easier transportation by road.

At AST, we manufacture the largest in diameter Type 3 COPVs. They offer maximum safety for transport and are able to handle high volume of gaseous hydrogen.

Our liners are produced in-house and carefully tested to our customer’s specifications. Book a call with us to learn more about what we can do for you today.

Alt: Type 3 COPV tanks

Geological Storage

Hydrogen derived from renewable energy can be stored in large quantities in its gaseous form.

The renewable energy from sources such as wind or solar is harvested during the summer or windy periods and stored underground for later use.

In geological applications, hydrogen gas is stored underground in large amounts.

Hydrogen can be stored in:

- Salt caverns

- Depleted oil and gas fields

- Aquifers

Liquified Hydrogen

Just like other energy sources, hydrogen can be liquified and stored in its liquid form.

For this application to be viable, hydrogen has to be stored in insulated tanks under cryogenic temperatures of -253 degrees C. This is done to prevent the evaporation of the fuel.

Liquified hydrogen is expensive to maintain. Also, 33% of the energy is lost during the liquefaction process.

The most suitable time liquified hydrogen is used is when it’s being transported over long distances and in large quantities.

Liquefying hydrogen enables transportation of larger volumes than the gaseous form.

Materials-Based Storage

Materials-based storage is when solids or liquids are used to bind hydrogen by chemical reaction.

The materials allow the absorption of hydrogen at room temperatures.

Hydrogen molecules normally repel each other, making it difficult to store the energy in a compacted space. The material components used in this application allow for storage at reduced pressure and higher volumes.

Research on how to improve materials-based storage of hydrogen is still ongoing. It’s believed that this method will offer more potential for hydrogen use in motor vehicles with increased capacity and reduced costs.

Hydrogen Storage Tanks

As said, hydrogen storage tanks are the best method to transport hydrogen because they limit risks of leakage and allow bulk transport by road.

This is a hydrogen storage breakthrough because it enables safe transportation and storage of hydrogen.

Hydrogen storage tanks enable:

- Stationary hydrogen storage: Storage in a facility ready for dispatch by trucks and storage vessels.

- Industrial hydrogen storage: Storage in an industry that uses hydrogen as a primary source of fuel.

Type 3 storage vessels are best for applications where capacity and portability are important. To get in touch with hydrogen tank manufacturers, click here.

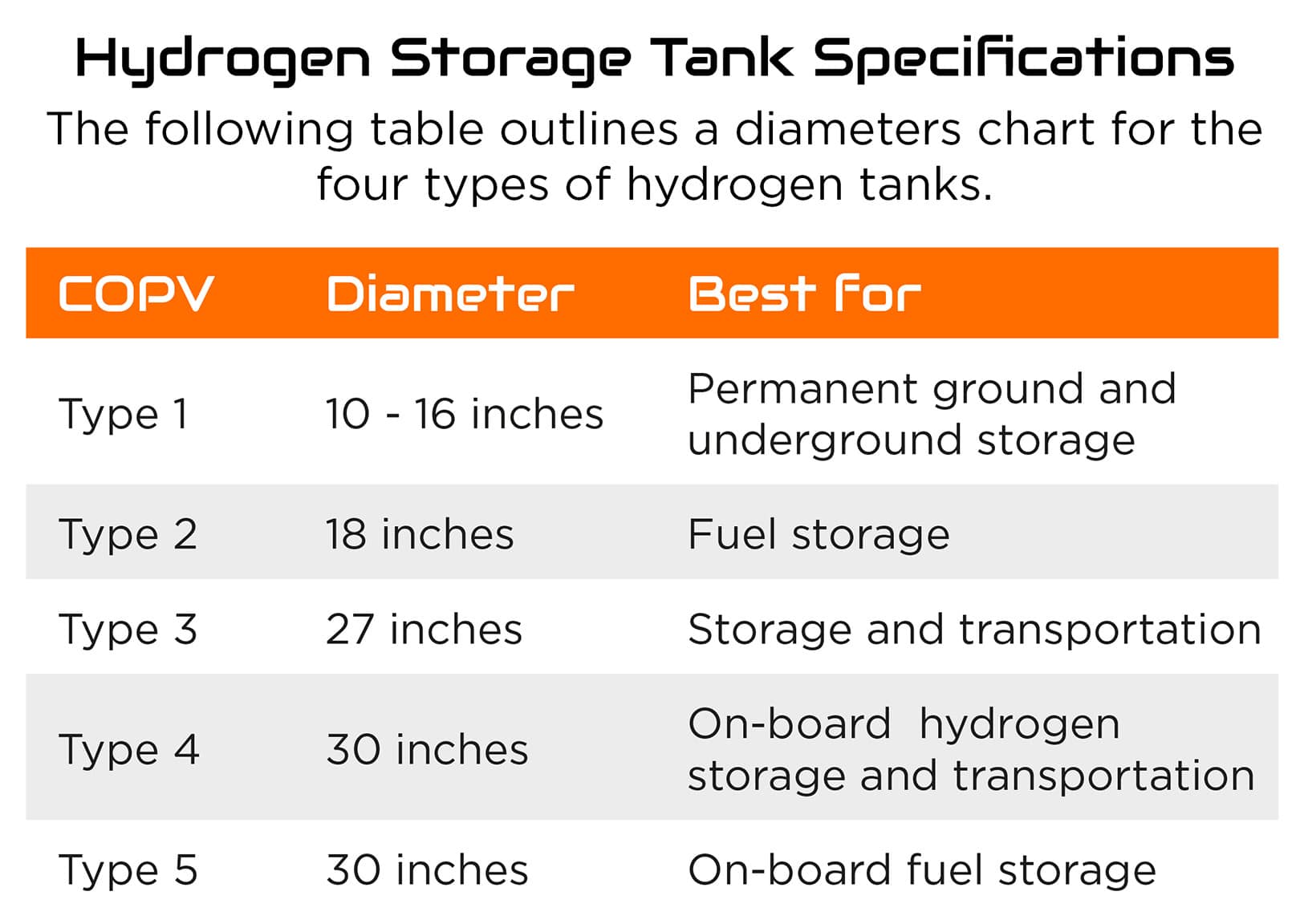

Hydrogen Storage Tank Specifications

The following table outlines a diameters chart for the four types of hydrogen tanks.

| COPV | Diameter | Best For |

| Type 1 | 10 to 16 inches | Permanent ground and underground storage |

| Type 2 | 18 inches | Fuel storage |

| Type 3 | 27 inches | Storage and transportation |

| Type 4 | 30 inches | On-board hydrogen storage and transportation |

| Type 5 | 30 inches | On-board fuel storage |

Hydrogen Transportation

Hydrogen transportation is largely determined by the original storage method.

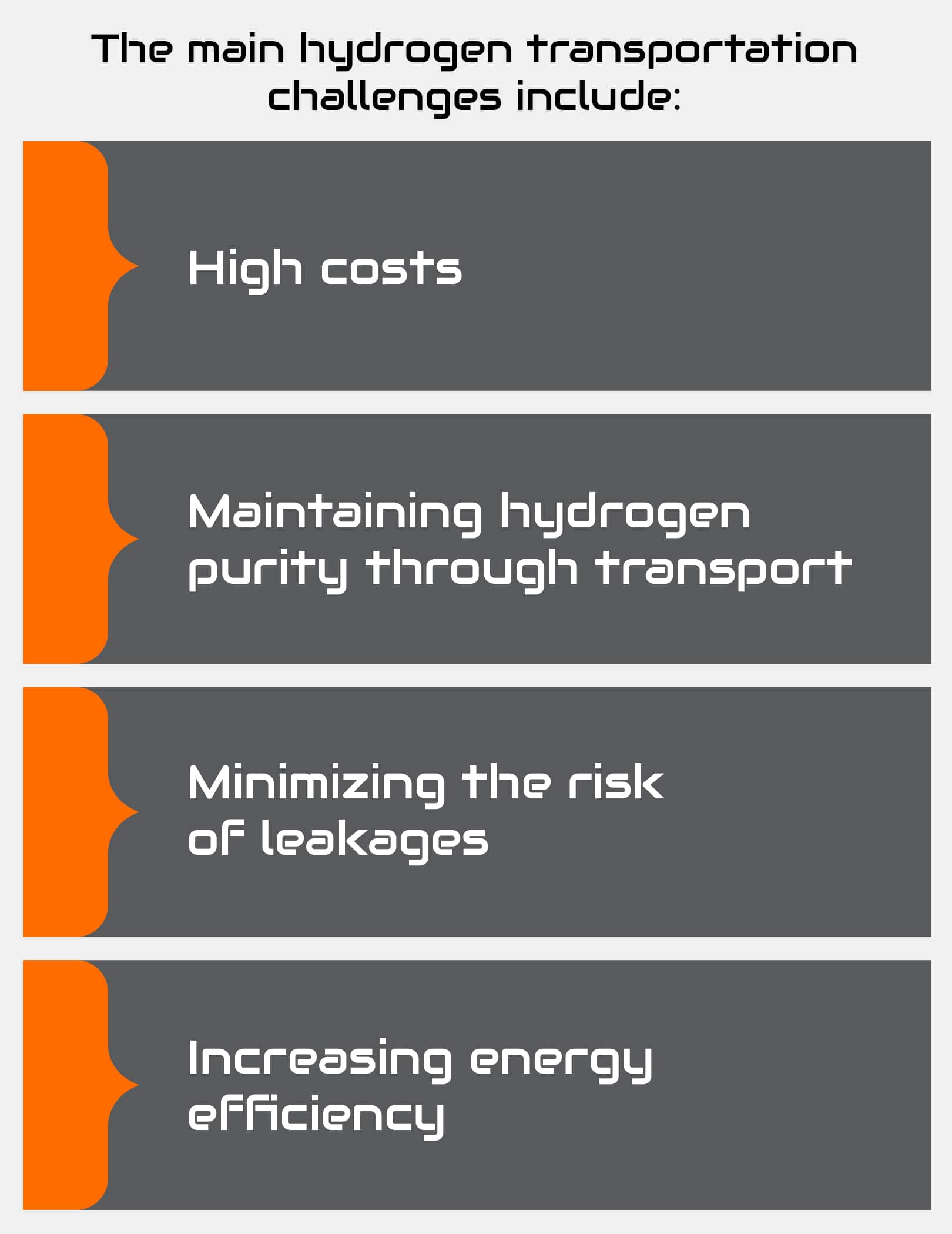

The main hydrogen transportation challenges include:

- High costs

- Maintaining hydrogen purity through transport

- Minimizing the risk of leakages

- Increasing energy efficiency

For each method of storage, we’ll provide advice on the suitable modes of transport.

Hydrogen Transportation Methods

Compressed Hydrogen

The best way to transport compressed hydrogen is via Type 3 storage tanks.

They offer a secure channel to keep the hydrogen safe and avoid permeation . They are also a better option for net kilograms of hydrogen transported for a single trip.

For Geological Storage

The best way to transport hydrogen from a geological site to the point of use is by pipelines.

This is because the hydrogen is stored in large amounts and it would have to either be liquified or compressed to be transferred to a different location.

Most terrains that allow for geological storage are also too rough and hence unfavorable for the passage of tankers.

Liquified Hydrogen

Cryogenic liquid tankers are suitable to carry liquified hydrogen. They are able to maintain low temperatures to avoid the evaporation of the hydrogen.

Materials-Based Storage

Materials-based storage is still in its infancy stages. There is no infrastructure available to transport this application.

Materials-based storage for hydrogen can only be used on site.

Safe Transport For Large Volumes of Hydrogen

To conquer the challenges that hinder the usage of hydrogen as the primary source of fuel, industry leaders must embrace the available storage and transport options for hydrogen.

Although research is still being conducted on how to make this easier, compressed hydrogen can be transported and stored safely using COPV tanks.

Type 3 COPV tanks offer quick refueling times, are resistant to high temperatures, and empty completely without any hydrogen residue.

At AST, we manufacture and test large diameter Type 3 COPV vessels that assure our customers’ safety when storing and transporting compressed hydrogen.

Book a call with one of our representatives to learn more about COPVs and hydrogen storage solutions suitable for your needs.