Metal Spinning – The Best Process for Spacecraft Components?

Forging and machining are traditional methods of producing spacecraft components like rocket combustion chambers or nozzle liners. Additive manufacturing (3D printing) is an emerging technique that promises to simplify the manufacturing process and thus captures a lot of attention for rocket nozzle and combustion chamber manufacturing.

While both techniques have their merits, a lesser-known method called “metal spinning” has emerged as a superior choice for rocket combustion chamber or rocket nozzle liners and other large, round aerospace components.

In this article, we’ll delve into the unique advantages of metal spinning and why it outshines other manufacturing methods in the demanding field of space exploration.

What are additive manufacturing and subtractive manufacturing?

Additive manufacturing (3D printing) builds objects by adding layers of material, while subtractive manufacturing (machining) shapes objects by removing material from a larger block.

Additive is for layer-by-layer creation, while subtractive is for material removal.

What is metal spinning?

Metal spinning sets itself apart by shaping solid input material metal directly to achieve the desired form, without the need for carving from solid blocks or layer-by-layer addition. Metal spinning conserves the amount of input material needed while still delivering the forged metal properties of product machined from forged stock.

Why is metal spinning a better method for spacecraft components manufacturing?

When it comes to manufacturing spacecraft components, metal spinning has proven itself to be the superior method for making large, round components like rocket nozzles and combustion chamber liners, outshining both additive and subtractive techniques.

With a long-standing history and a track record of success, metal spinning deserves recognition as a prime manufacturing process for the space market we proudly serve at AST.

Let’s look at its wide range of advantages…

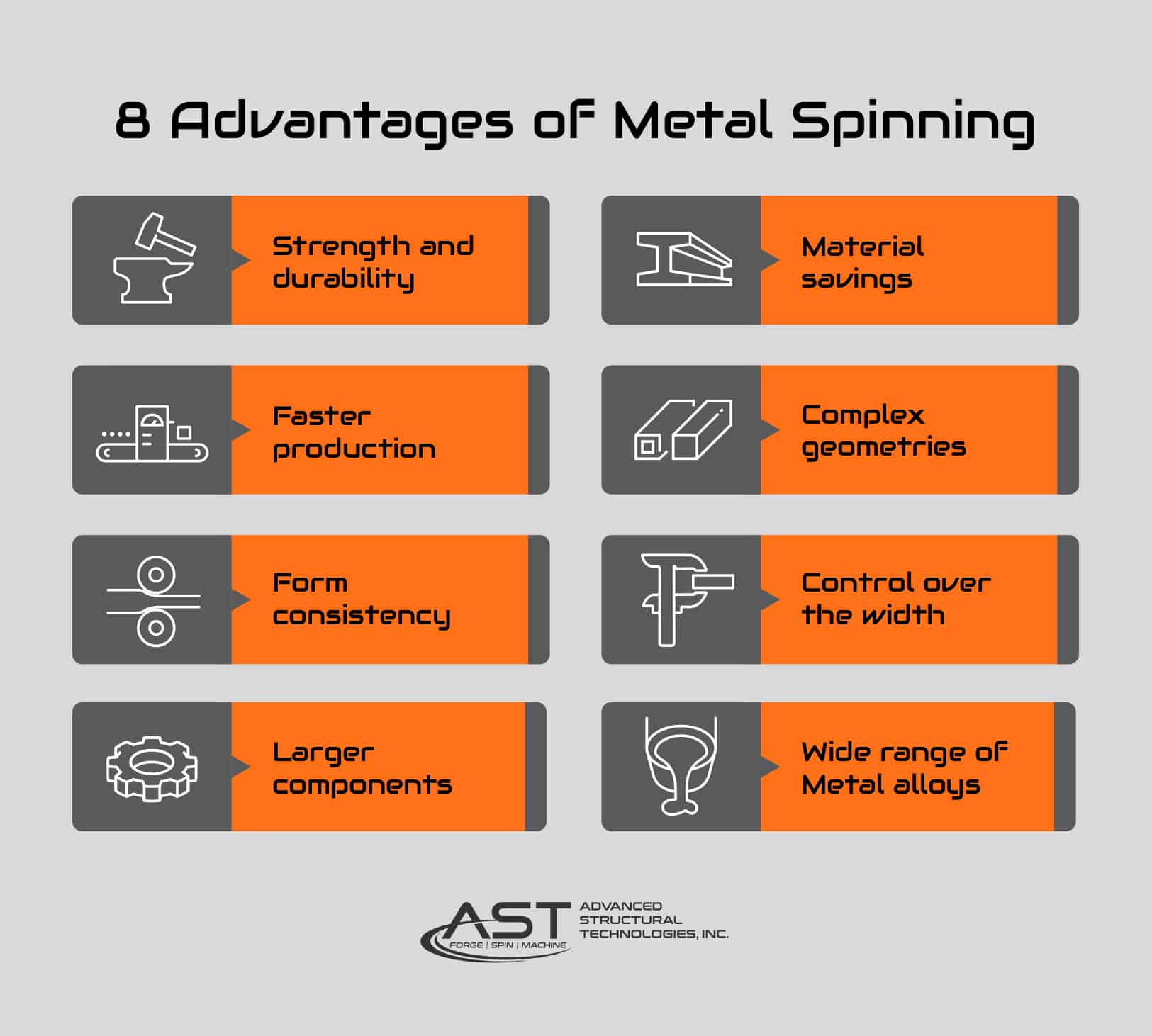

8 Advantages of Metal Spinning:

There are 8 specific benefits of advanced metal spinning over other methods, when it comes to manufacturing large, round spacecraft components.

1. Strength and durability

The metal properties are comparable to forged metals. Through careful control of grain flow and grain size, the hoop strength of our parts can be improved by around 3 to 4%.

This is particularly valuable for applications where even slight improvements in strength make a significant impact.

By skillfully shaping the metal through spinning, we harness the benefits of forging, ensuring the reliability and performance required in the demanding field of space exploration.

2. Material savings

Unlike subtractive processes that involve removing excess material from a solid block, metal spinning optimizes resource utilization by directly shaping the metal to the desired shape.

This not only reduces waste but also offers cost savings while promoting sustainability—a key consideration in today’s manufacturing landscape.

💡For some of our customers, the amount of material used has been reduced by as much as nine times.

3. Faster production

The metal spinning process allows for producing a part that has no seams and no welds.

Processes that involve making rings and then welding them together are time consuming. In our metal spinning process those steps are eliminated.

This result is a much faster production with metal spinning.

4. Complex geometries

Precision and control are inherent to metal spinning, enabling us to achieve intricate designs and complex shapes with exceptional accuracy.

With our skilled craftsmen manipulating the metal on spinning lathes, we ensure the utmost precision required for space components. The ability to achieve such fine-tuned results is crucial in the space industry, where every detail matters and deviations can have significant consequences.

5. Form consistency

Advanced metal spinning can produce parts that are consistently round, unlike alternative methods that involve welding together wrapped sheet metal.

This ensures uniform metal properties throughout the part and maintains a higher level of “roundness”.

6. Control over the width

Customers get control over the width of their parts.

Because our manufacturing process enables flaring and closing of the ends, making it versatile and adaptable to various applications.

For example, it can be used to create seamless tanks that are both lighter and structurally sound.

7. Larger components

We’re able to make parts that are 80 inches tall, 80 inches wide. And we can go even larger.

For contrast, 3D printing maxes out at around 40 inches.

8. Wide range of Metal alloys

Metal spinning’s versatility extends to its compatibility with a wide range of Metal alloys.

Whether it’s aluminum, titanium, stainless steel, or specialized alloys, metal spinning provides an effective means of shaping and working with diverse metals commonly utilized in aerospace applications.

This versatility allows us to meet the stringent requirements and industry standards of the space sector, ensuring the production of components that meet the highest quality and performance benchmarks.

While metal spinning takes center stage in space component manufacturing, it is important to note that there will always be a complementary subtractive process involved.

This typically takes the form of machining to achieve precise dimensions and fine-tune the finished components.

However, metal spinning sets the foundation for the production process, enabling us to leverage its unique advantages and ultimately deliver superior space components.

What is the metal spinning process?

Metal spinning involves subjecting natural materials such as metals and alloys to immense heat and strain, pushing them to their limits.

The process requires meticulous attention to detail, as even minute variations can significantly impact the final outcome.

Through a combination of computer control, precision calculations, and real-time observations, our engineers ensure that every step of the process aligns with the intended design.

What is the future of advanced metal spinning?

Metal spinning offers significant improvements over traditional methods, making it applicable for heavy-lift rockets and large thrust engines.

As there is a growing demand for copper alloys in various industries, including rocket engines, alternative energy, and aircraft, using materials economically and efficiently becomes crucial.

Ongoing innovation is expected, with a focus on scaling up and making seamless parts larger and more efficiently.

There is also potential for hybrid approaches, combining metal spinning with other technologies like 3D printing or subtractive processes, to further enhance capabilities and meet evolving needs.

AST’s Metal Spinning Quality Control Process

To ensure quality and accuracy in manufacturing, various steps are taken throughout our process.

This includes:

1. Precise measurements of dimensions and temperatures

2. Material tests and sampling

3. Thorough preparation

4. Equipment Maintenance and upgrades

The experience we gain during the process helps us identify areas for simplification and improvement.

Collaboration with customers is crucial in reducing unnecessary steps, combining operations, and optimizing designs.

The focus is on making the manufacturing process simpler, more reliable, and as efficient as possible.

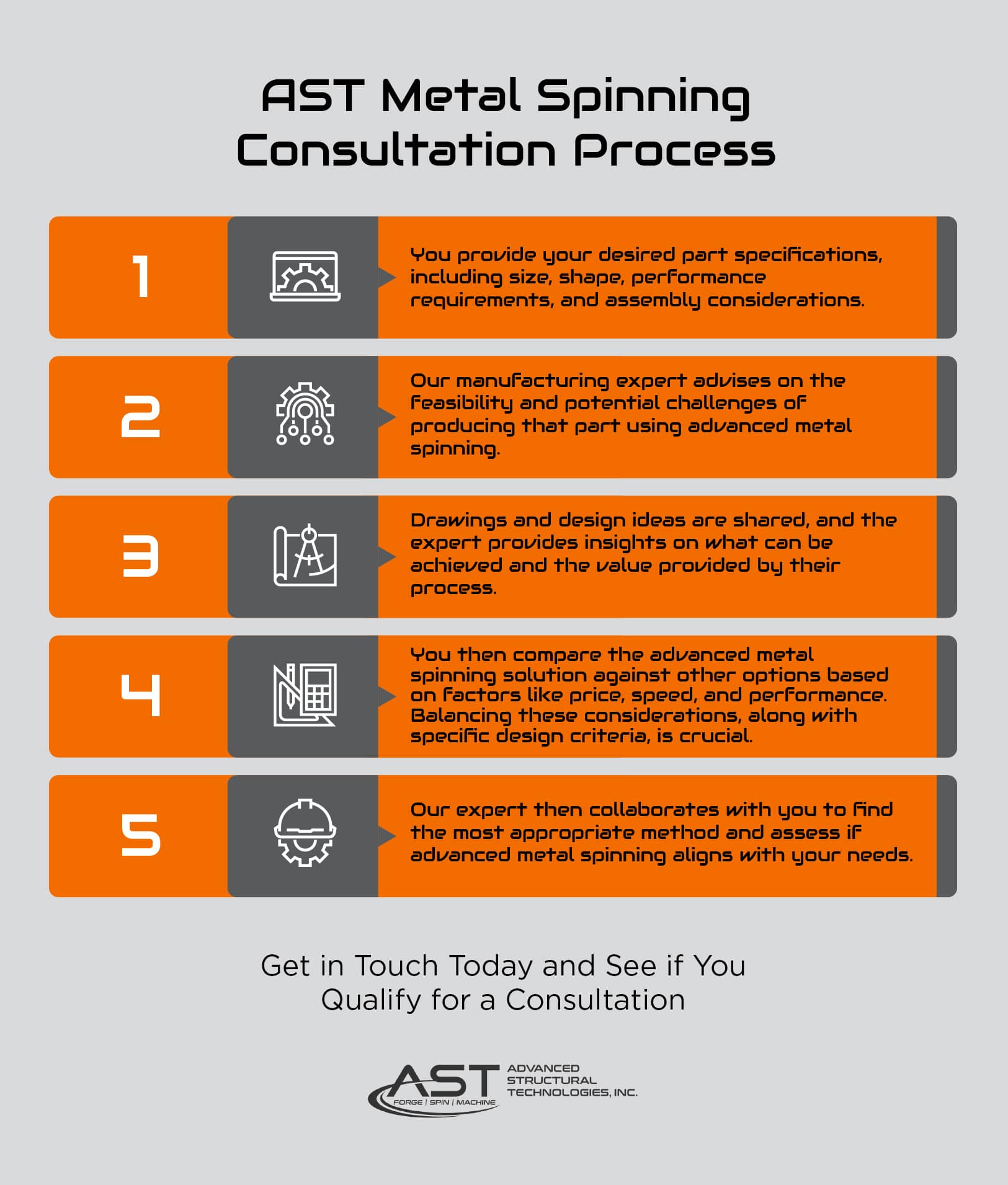

Is metal spinning right for you?

When helping a customer decide between advanced metal spinning and other manufacturing methods, our approach is consultative.

Here’s how it works:

1. You provide your desired part specifications, including size, shape, performance requirements, and assembly considerations.

2. Our manufacturing expert advises on the feasibility and potential challenges of producing that part using advanced metal spinning.

3. Drawings and design ideas are shared, and the expert provides insights on what can be achieved and the value provided by their process.

4. You then compare the advanced metal spinning solution against other options based on factors like price, speed, and performance. Balancing these considerations, along with specific design criteria, is crucial.

5. Our expert then collaborates with you to find the most appropriate method and assess if advanced metal spinning aligns with your needs.

Ultimately, our goal is to provide the best solution for your specific scenario.

Get in touch now to see if you qualify for a consultation.